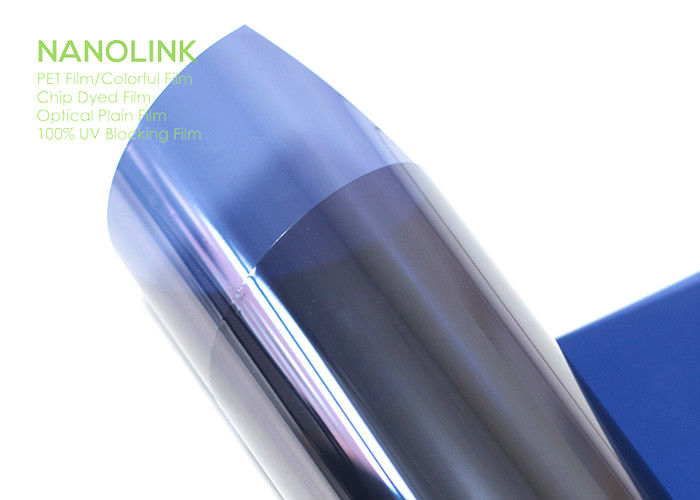

100% Anti UV Car Window UV400 series Solar Window Tint Film With Skin Protection

Nano ceramics series for all automotive/commercial/residential; non-reflective ceramics apply on the films. IR ceramics film is a non-metalized coating film. It is known for best Infrared rejection. High in transmission for visible light, and low outer light reflection; the series could be use both for cars and buildings.

| Type |

nano ceramic series |

Item name |

UV400-65100 |

| Color |

light blue |

thickness |

50um |

| VLT |

65% |

Application |

car side window&buidling window |

| IR rejection |

99% |

MOQ |

1 ROLL |

| UV rejection |

100% |

Standard size |

1.56*4000m |

| Material |

PET |

Brand name |

nanolink |

| warranty |

15years |

Package |

pallet |

| OEM |

Available |

|

|

| Item |

Unit |

Reference Value |

Test Value |

| Average Thickness |

μm |

23 |

23±1 |

| Tensile Strength |

MD |

Kg/mm2 |

33 |

27±5 |

| |

TD |

Kg/mm2 |

27.5 |

26±5 |

| Elongation |

MD |

% |

126 |

140±40 |

| |

TD |

% |

110 |

130±40 |

| Heat Shrinkage |

MD |

% |

1.4 |

1.5±1 |

| |

TD |

% |

0.3 |

0±1 |

| Friction Shrinkage |

US |

- |

0.25 |

0.4±0.2 |

| |

UK |

- |

0.22 |

0.3±0.2 |

| Haze |

% |

1.5 |

≤2.0 |

| Definition |

% |

99.8 |

≥99 |

| Wetting Tension |

Dyne/cm |

52 |

≥50 |

| VLT |

% |

88 |

88±2 |

| IRR |

% |

11 |

11±2 |

| UVR |

% |

99 |

99±1 |

Innovation& Quality is our eternal belief!

Nanolink has nanometer metallic oxide preparation, grinding scattering, modified function of masterbatch as core technology, and is based on the research and development of functional materials from optical PET film. Products are widely used photoelectricity, construction, automobile and other fields, innovation and quality is our eternal belief!

Combine·Exceed for Nanolink Materials

In order to maintain the worldwide technological competitiveness and open up a new field for film materials, Nanolink integrates the technology of functional masterbatch dispersion, aggregation, BOPET and online surface coating. Combine now·Exceed future...

Advantage

Nanolink has independent research and development of advanced technology, superior R&D philosophy, well-stocked supply of raw material and senior-level technical support, as well as the strict quality control, can produce film of advanced technology, and serve to markets, in which terminal users increase rapidly around the world.

Laboratory

Laboratory of Nanolink is a space station, which can let people more close to the future, and scientists innovate, who have a common goal. Innovation is everywhere.We make a dream and read a dream...

Company’s background

Shanghai Nanolink Materials Co., Ltd is a high-technology enterprise, which has nanometer materials preparation, grinding scattering, modified function of masterbatch as core technology, is based on the research and development of functional materials from optical PET film, and integrates the technology of functional masterbatch dispersion, aggregation, BOPET and online surface coating.

in the foreseeable future, Nanolink will use its own advanced technology and intellectual property rights, integrate the world's leading expert team, and continue to invest in the existing and future advanced technology, in order to realize the development goals and look forward to more breakthrough in the film industry in the near future.

Core products of Nanolink current : PET Chip Dyed Film, high blocked UV film, color electronic tape of base film , carbon black (kaben series) constant color of base film, etc.

Production equipment: German Bruckner Production Line

This production line is current most advanced plastic film in the world, computer can control and complete the speed, pressure and temperature of running automatically, regardless of the quality, production and energy consumption of the product has big superiority.

Technology line

Unique technology of three-layer co-extrusion (transparent 3 μ+ color 17 μ+ transparent 3 μ)

Unique technology of three-layer co-extrusion from Nanolink can randomly assemble all kinds of functional materials and develop rich products.

Research & Development Center

We have professional talent team to development of nanometer materials, technology of UV curing and molding, precision coating, technology of extrusion and molding, vacuum sputtering, etc., research and develop to produce the most excellent window films, which can meet customer’s requirement, and at the same time can also make innovative advantaged products, which suit dynamic development of the market.Because of profound originality and persistent research and development, window films of Nanolink have infinite vitality!

Now our current products as below :

Inorganic nanoparticles Ceramic Chip Dyed Series

| Model |

VLT |

IR |

Haze |

Weather resistance time |

UV Blocking |

| IR 7080 |

70% |

80% |

0.5% |

10Years |

48% |

| IR8080 |

80% |

80% |

0.5% |

10Years |

41% |

| IR2080 |

20% |

80% |

0.5% |

10Years |

86% |

| IR7040 |

70% |

40% |

0.5% |

10Years |

99% |

Organic Chip Dyed Series

| Model |

VLT |

IR |

Haze |

Weather resistance time |

UV Blocking |

| TUV16 |

13% |

40% |

1.5% |

2-3Years |

100% |

| TUV25 |

22% |

40% |

1.5% |

2-3Years |

100% |

| TUV30 |

29% |

40% |

1.5% |

2-3Years |

100% |

| CD15918 |

18% |

13% |

1.5% |

2-3Years |

40% |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!